Boiler performance boiler, like efficiency and evaporation ratio, reduces with time due to poor combustion, heat transfer surface fouling and poor operation and maintenance. Even for a new boiler, reasons such as deteriorating fuel quality and water quality. This can result in poor boiler performance. A heat balance helps us to identify avoidable and unavoidable heat losses. Boiler efficiency tests help us to find out the deviation of boiler efficiency from the best efficiency and target problem area for corrective action.

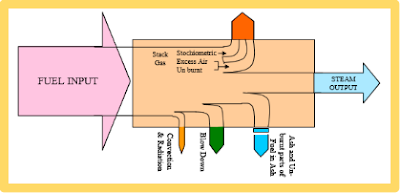

The combustion process in a boiler can be described in the form of an energy flow diagram. This shows graphically how the input energy from the fuel is transformed into the various useful energy flows and into heat and energy loss flows. The thickness of the arrows indicates the amount of energy contained in the respective flows.

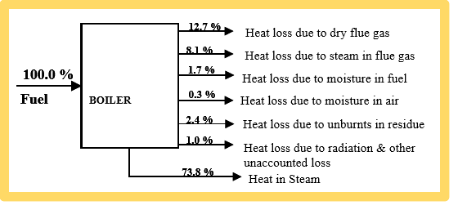

A heat balance is an attempt to balance the total energy entering a boiler against that leaving the boiler in different forms. The following figure illustrates the different losses occurring for generating steam

The energy losses can be divided in unavoidable and avoidable losses. The goal of a Cleaner Production and/or energy assessment must be to reduce the avoidable losses, i.e. to improve energy efficiency. The following losses can be avoided or reduced:

- Stack gas losses:

– Excess air (reduce to the necessary minimum which depends from burner technology, operation, operation (i.e. control) and maintenance).

– Stack gas temperature (reduce by optimizing maintenance (cleaning), load; better burner and boiler technology).

- Losses by unburnt fuel in stack and ash (optimize operation and maintenance; better technology of burner).

- Blow down losses (treat fresh feed water, recycle condensate)

- Condensate losses (recover the largest possible amount of condensate)

- Convection and radiation losses (reduced by better insulation of the boiler).