Blowdown Boiler

Boiler Blowdown Calculation – Calculation of BlowDown Capacity required in water tube boiler operations for example in boilers with a capacity of 40 tons per hour, we often encounter changes in boiler water quality due to changes in water quality such as in the palm oil industry. Changes in water quality that often occur include changes in TDS and PH. One example that is often experienced in the Palm Oil Mill industry is the sudden change in Boiler water quality due to weather changes. If there is a sudden change in weather, such as heavy rain, it will certainly affect the quality of the raw water from the water source (reservoir or river). Therefore, the task as a supervisor must play a role in maintaining it properly. We know that changes in water quality will also affect the life time of the water tubes we use. But we will discuss this at a later time. For now we will discuss about calculating the amount of boiler water blowdown.

Accurate boiler blowdown calculations are critical to the safety of your boiler

Boiler Blowdown Calculation – This article presents an example of calculating the blowdown rate (blowdown rate) and the duration of the blowdown (blowdown time). It should be understood that boiler feed water or boiler feed water still contains impurities as dissolved solids which are commonly referred to as Total Dissolved Solids (TDS). Impurities that continue to enter the boiler will accumulate quickly in the boiler, because the boiler water continues to become steam.

If the accumulation of TDS is allowed, there will be boiler problems such as blockage and overheating. To avoid this problem, it is necessary to process sewage with the right calculation of boiler blowdown.

Example of Boiler Blowdown Calculation

Based on field data, it is known as follows:

Steam flow boiler : 27 ton/hour (View from control panel)

Maximum boiler TDS : 1900 ppm

TDS feed water : 100 ppm

So, what is the blowdown rate and blowdown time?

Answer:

Calculating Boiler Blowdown Rate

Blowdown rate is the rate of blowdown or the amount of dirty water in the boiler that must be discharged every hour. Usually expressed in tons per hour. The purpose of calculating the blowdown boiler rate is to ensure that the amount of dirt that must be removed will be completely completed so that your boiler will always be at a safe level.

Blowdown rate = Steam Flow / (Cycle – 1)

Cycle (C) = TDS Boiler Max / TDS Feed Water

= 1900/100

= 19

So:

Blowdown rate = (27 tons/hour) / (19 – 1)

= 1.5 tons/hour

So, to keep the boiler at a safe level against the accumulation of impurities (maximum TDS 1900 ppm), a blowdown rate of 1.5 tons/hour is required.

Boiler Blowdown Calculation, Calculating Boiler Blowdown Time

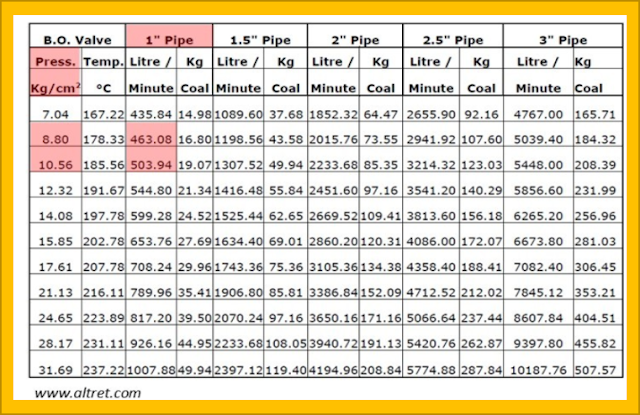

Furthermore, to determine the duration of the blowdown or blowdown time of the boiler, it is necessary to know the diameter of the blowdown pipe and its working pressure, then refer to the table below for the calculation.

If it is known that the diameter of the blowdown pipe = 1” and the pressure = 9.5 Kg/cm2, then the duration of the blowdown can be calculated by interpolating the data. Pay attention to the red numbers in the table above, the main benchmark is the actual pressure value.

Since the actual pressure is 9.5, the pressure data for interpolation calculations are 10, 56 and 8.8 (because 9.5 lies between these ranges). By looking at the pipe diameter column, the following data interpolation equation is obtained:

(10.56 – 8.8) / (9.5 – 8.8) = (503.94 – 463.08) / (x – 463.08)

So we get:

x = 480 liters/minute

For a blowdown rate of 1.5 tons/hour when applied to a 1″ diameter blowdown pipe with a pressure of 9.5 Kg/cm2, the duration of the blowdown is required:

= (1.5 tons / hour) / (480 liters / minute)

= (1,500 liters / hour) / (480 liters / minute)

= 3.13 minutes/hour

(In every hour, the blowdown valve is opened for 3.13 minutes).

The results of the boiler blowdown calculation above are used as the basis for the implementation of blowdown either manually or automatically.

For more informations and knowledge in indonesian languange, you can visit this site industry.